Selection of PV modules

Types / Advantages and disadvantages

We are now only talking about panels with monocrystalline solar cells:

These panels consist of individual silicon crystals and offer high efficiency, but are more expensive to manufacture than the polycrystalline solar cells used previously.

With modern modules, we are talking about efficiencies of over 20% .

Newer models like Tongwei , Trina , or Canadian even have efficiencies of 22-24%. This allows for higher outputs with the same surface area.

Explanation of terms:

You will repeatedly encounter the following terms, which we would like to briefly explain here:

- PERC technology (Passivated Emitter Rear Cell): PERC technology uses an additional layer on the back of the solar cell to utilize the reflection of light and increase efficiency.

- Bifacial modules: These modules can capture light from both sides by utilizing the reflected light from surfaces such as water or snow. This increases energy yield.

- Glass/glass modules: This describes the panel's construction. Therefore, it has glass on both the front and back, unlike glass/film modules (which have glass on the front and a plastic film on the back). A quality rating can be derived from this.

- Half-cell photovoltaic modules: Half-cell photovoltaic modules are an evolution of conventional monocrystalline or polycrystalline photovoltaic modules. The main difference is that the solar cells in these modules are divided into two halves, resulting in smaller cells. These smaller cells offer several advantages: lower power losses, better heat dissipation, and a longer lifespan.

- Shingled technology: Shingled technology is an innovative method for arranging solar cells in photovoltaic modules. Unlike conventional modules, where the cells are arranged flat, this technology places them overlapping like shingles on a roof. This further subdivision of the cells, compared to half-cell modules, results in even better shading properties. However, the production process is more complex, and therefore the price is higher. Shingled technology offers the following advantages: increased mechanical stability, improved shading properties, and better low-light performance – thus also resulting in higher energy yields in the morning and evening.

- N-type; P-type cells: The difference compared to conventional P-type modules lies in the doping. In P-type cells, the crystalline silicon wafer is positively doped with boron, while in N-type cells it is negatively doped with phosphorus. N-type cells have a longer lifespan and also better low-light performance. This means, similar to shingled modules, more power is produced in low sunlight conditions, such as in the early morning and at sunset.

- TopCon Technology: This technology was presented by the Fraunhofer Institute for Solar Energy Systems (ISE) in 2013. It consists of n-type solar cells with passivating contacts. The modules feature strong surface passivation and effective charge carrier transport, contributing to high open-circuit voltage and high efficiency. This minimizes the metal-to-silicon contact.

- Bypass diodes: Virtually every modern PV module uses bypass diodes to switch off the power supply when shaded. The misconception persists that shading of modules, or even just parts of the PV cells, leads to a drop in the overall system's power output. This was indeed the case in the past. However, since the advent of inexpensive bypass diodes, this is no longer the case. Where power optimizers were previously required, the diode (usually three or more) now performs this function. The diode switches off the shaded portion of the module. Naturally, this results in a power loss (but only by the amount of power that is bypassed by the diode).

- Optimizer: Power optimizers are usually mounted directly onto the PV modules and serve to optimize performance under unfavorable conditions. Previously used primarily in shading situations, they are now only useful when combining modules with different orientations.

Example : In this example, a string should consist of at least 5 modules, each with 40 V (MPP), connected in series to achieve the inverter's MPPT start voltage of 200 volts. However, if there is only enough space for 2 modules on the east side and 3 on the south side, they cannot simply be connected together. The southern modules would slow down the eastern modules in the morning, and the eastern modules would slow down the southern modules from late morning onwards.

When optimizers are connected to the modules, they scan the grid to detect the available MPPT voltage. This voltage is then generated by the optimizers and supplied to the system. Internally, on the primary side facing the module, the voltage selected is the one the module considers optimal to generate maximum power from the module. Thus, each module delivers its full potential power without interfering with the others.

MPP tracking (Max Power Point Tracking): In short, MPPT simply means that the inverter searches for the point where it receives maximum power from the module or string of PV modules. This point is recalculated by the inverter at regular intervals to react to changes in the sun's position, temperature, cloud cover, or shading.

Most manufacturers adjust the MPPT curve in two steps. First, to achieve the optimal MPPT value, and then at larger intervals away from 0V to detect, for example, shading. This is called active shadow management.

This is regulated by increasing the voltage until the maximum current and thus the maximum power is achieved.

How do I choose the optimal module for me?

It is important to understand beforehand that the modules generate the power, which is why they are also called generators.

Anything the modules fail to produce or lose due to poor planning cannot be compensated for by the system. And the modules are usually the largest investment factor in a PV system.

Therefore, the modules are indeed the heart of a system, not the inverter. The inverter is also important, but relatively easy to replace if incorrectly configured – unlike the modules.

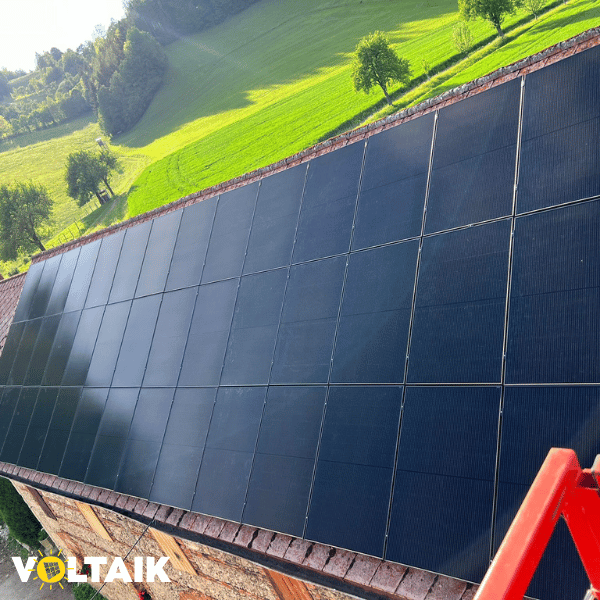

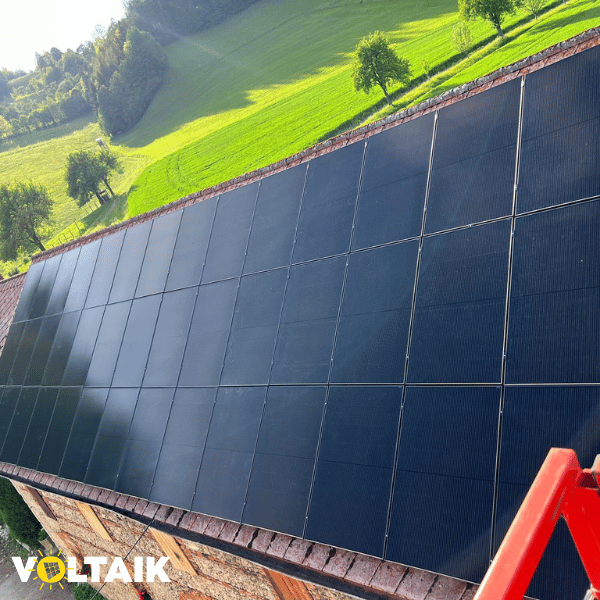

If the modules are mounted on a roof, the environmental influences must be taken into account:

- What are the wind speeds and snow loads ?

- Are there any shadows , or is there often morning fog ?

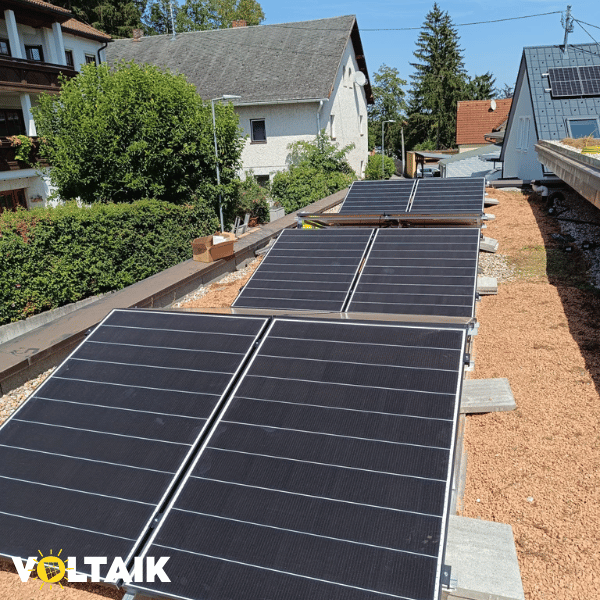

open space facilities

- How can the modular panels be mounted? Vertically or at an angle?

- With tracking, or at what level (keyword: AGRI PV)

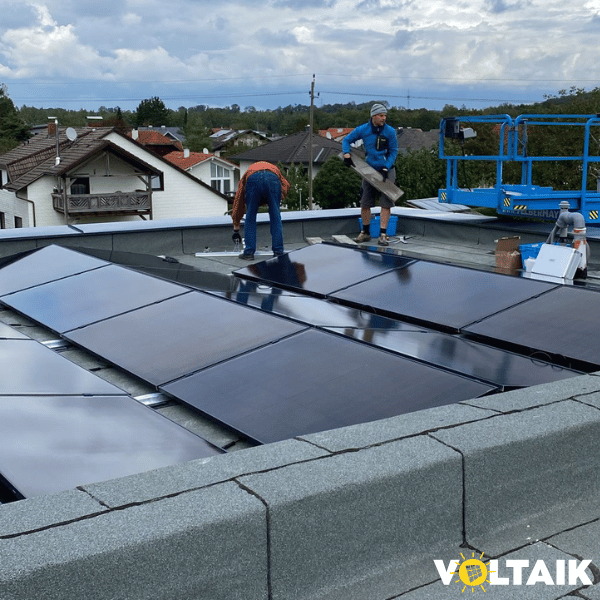

Facades or overhead installations, e.g., for carports

- What building regulations apply to glass?

- Optical aspects

General aspects:

- How many modules can be connected in series without exceeding the maximum voltage of the inverter?

- How high will this voltage be in winter at -15°C?

- What is the maximum performance achievable per string (i.e., per string length)?

- How many strings can or should be executed?

Snow and wind load: The information can be found on the module's datasheet under the heading "mechanical parameters".

The values 2400/5400 Pa are usually stated here. This means that it can withstand a wind pressure of approximately 250 kg or a snow load of 550 kg/m² (1 Pascal = 1 N/m² → 1 kg = 9.81 N).

If this module measures 1770 mm x 1130 mm (i.e., 2 m²), it can withstand a snow load of approximately 1100 kg without breaking.

The types of loads to be assumed can be determined on various websites (e.g. OBO).

Glass-glass modules often achieve top results here. However, it's important to note that in our latitudes, snow weight (except in the Tyrolean mountains) is rarely the decisive factor, but rather extreme environmental events like hailstorms . In such cases, the maximum surface load isn't the determining factor; instead, the thickness of the front glass can provide a clue as to which module is preferable. Ideally, hail resistance specifications should be provided.

A bifacial glass/glass module with 1.6 mm glass on the front would be at a disadvantage compared to a 3.2 mm glass of a glass/film module .

Maximum voltage (Uoc = open-circuit voltage) = maximum string length: To maximize the coverage of an area, the voltage (Voc) must be considered in addition to the module size. The voltage is calculated to increase by up to +20% in winter (the temperature coefficient of Voc must be taken into account here). Therefore, with an inverter that can handle a maximum input voltage of 1000 V and modules with a Voc of 50 V, a maximum of 800 V can be expected. This means that a maximum of 16 modules can be connected in series. It is therefore worth considering whether to switch to modules with a Voc of only 40 V, which would allow for 20 modules in series.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.